Tsanangudzo

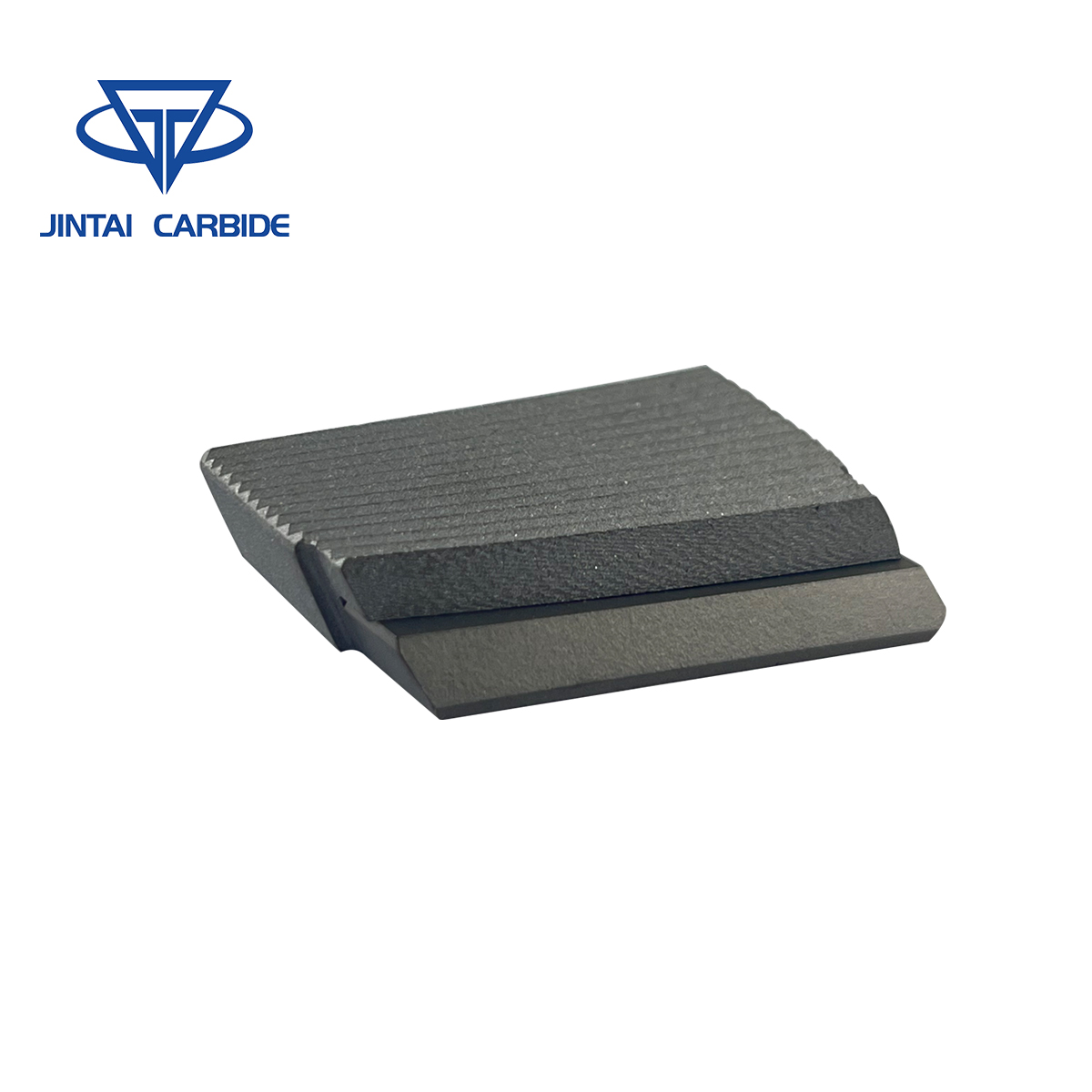

"JinTai" kutsika kunofa uye musoro unotonhora unofa

Features:

Sarudza giredhi rakakodzera zvichienderana nekushandiswa chaiko kwemutengi uye zvinhu zviri kugadziriswa.Iine akasiyana tungsten simbi inotsikirira magiredhi ekufa, inogona kusangana nezvinodiwa zveakasiyana mashandisirwo, akazara maratidziro, chaiwo asina chinhu zviyero, kuderedza vhoriyamu yekugadzirisa, uye kuvandudza kushanda nesimba uye mutengo-kubudirira.

Kuita:

Uchishandisa 99.95% high-purity raw material tungsten carbide poda uye cobalt, kuoma kwemusoro unotonhora kunofa kunosvika pamusoro peHRA88, simba rekukotama rinopfuura 2400, nekuoma kwakatsvuka kwakanakisa, kupfeka kwepamusoro, kukwirisa elastic modulus, simba rekukotama rakakwirira, uye kusimba kwesimba kuramba. .

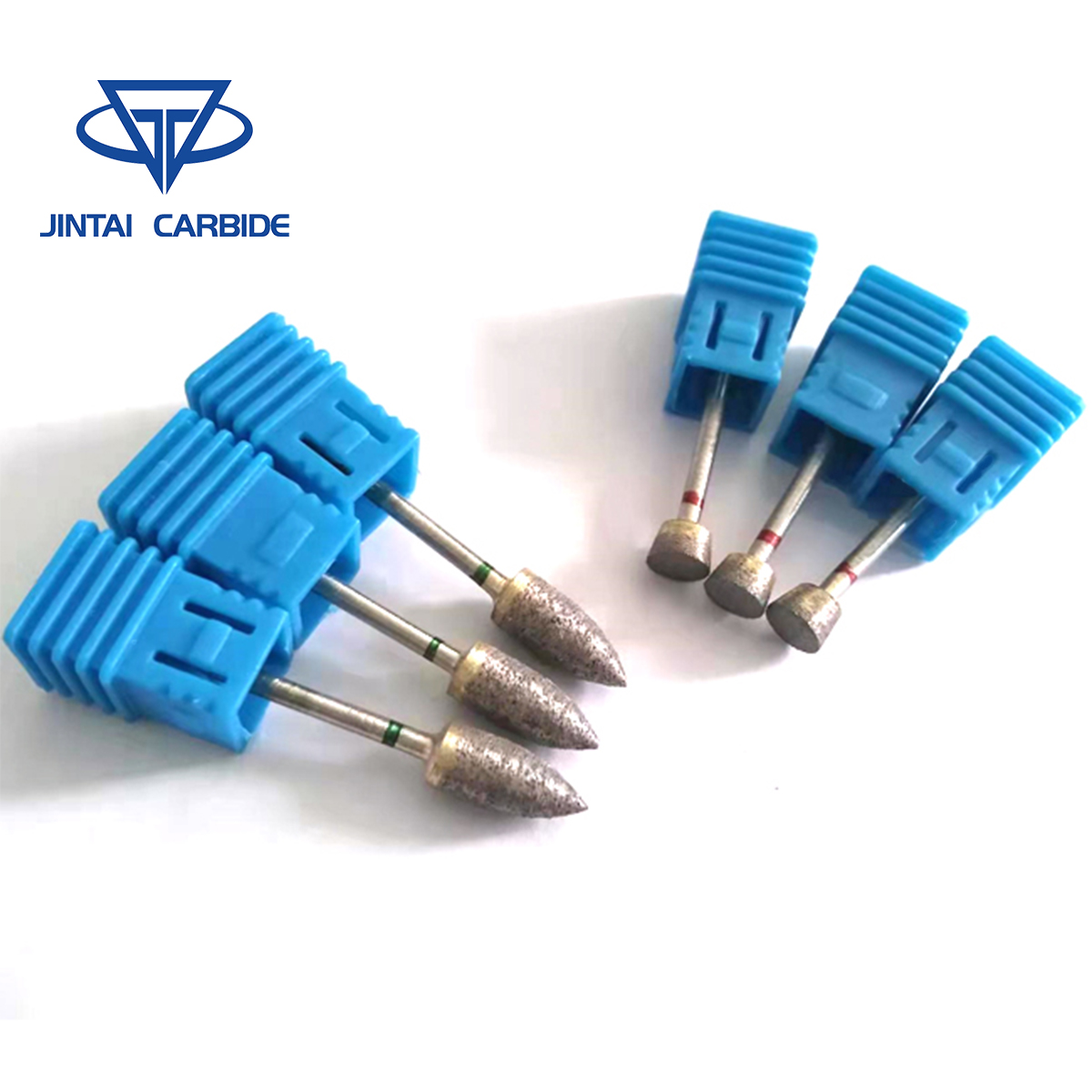

Applications:

Inokodzera musoro unotonhora uye inotonhora extrusion yezvakajairwa zvikamu zvakagadzirwa nemhangura, aruminiyamu, simbi, alloy simbi zvinhu, senge screws, rivets, etc. Mhando dzakajairika dzinosanganisira flat musoro inotonhora musoro inofa, yakadzoreredzwa musoro inotonhora inofa, imwe-inoteedzana punch uye kufa, tsvimbo yekudzikisa inofa, nezvimwe.

Kutsika Kunofa Musoro Unotonhora Unofa

Features:

Sarudza giredhi rakakodzera zvichienderana nekushandiswa chaiko kwemutengi uye zvinhu zviri kugadziriswa.Iine akasiyana tungsten simbi inotsikirira magiredhi ekufa, inogona kusangana nezvinodiwa zveakasiyana mashandisirwo, akazara maratidziro, chaiwo asina chinhu zviyero, kuderedza vhoriyamu yekugadzirisa, uye kunatsiridza kushanda zvakanaka uku uchideredza mitengo.

Kuita:

Uchishandisa 99.95% high-purity raw material tungsten carbide poda uye cobalt, kuoma kwemusoro unotonhora kunofa kunosvika pamusoro peHRA88, simba rekukotama rinopfuura 2400, nekuoma kwakatsvuka kwakanakisa, kupfeka kwepamusoro, kukwirisa elastic modulus, simba rekukotama rakakwirira, uye kusimba kwesimba kuramba. .

Applications:

Inokodzera musoro unotonhora uye inotonhora extrusion yezvakajairwa zvikamu zvakagadzirwa nemhangura, aruminiyamu, simbi, alloy simbi zvinhu, senge screws, rivets, etc. Mhando dzakajairika dzinosanganisira flat musoro inotonhora musoro inofa, yakadzoreredzwa musoro inotonhora inofa, imwe-inoteedzana punch uye kufa, tsvimbo yekudzikisa inofa, nezvimwe.

Corrosion kuramba kwakakosha kana zvasvika pakuchengetedza kunaka kwepamusoro uye kushanda kwenguva refu.Yedu tungsten carbide inofa yakanyatso gadzirwa kuti inyatso kurwisa corrosion.Aya ma mold anoshingirira mukuora uye anochengeta nzvimbo dzako dziri mupristine mamiriro, kuve nechokwadi kupera kwakakwana nguva dzese.Unogona kuvimba nema molds edu kuti amire muyedzo wenguva uye nekuunza mhedzisiro yepamusoro nekushandisa kwese.

Ingave iri dhizaini yakasarudzika, saizi yakasarudzika kana chaiwo maitiro ekuita, timu yedu yenyanzvi yakatsaurirwa kuendesa mold inodarika zvaunotarisira.

Corrosion kuramba kwakakosha kana zvasvika pakuchengetedza kunaka kwepamusoro uye kushanda kwenguva refu.Yedu tungsten carbide inofa yakanyatso gadzirwa kuti inyatso kurwisa corrosion.Aya ma mold anoshingirira mukuora uye anochengeta nzvimbo dzako dziri mupristine mamiriro, kuve nechokwadi kupera kwakakwana nguva dzese.Unogona kuvimba nema molds edu kuti amire muyedzo wenguva uye nekuunza mhedzisiro yepamusoro nekushandisa kwese.

Ingave iri dhizaini yakasarudzika, saizi yakasarudzika kana chaiwo maitiro ekuita, timu yedu yenyanzvi yakatsaurirwa kuendesa mold inodarika zvaunotarisira.

Sunungura kugona chaiko kweTungsten Carbide Molds!Semuchinjika-muganho e-commerce connoisseur, iwe wasvika panzvimbo yakanaka yekuenda yepamusoro-ye-iyo-mutsara Tungsten Carbide Molds inokunda mumhando dzakasiyana dzekuumba maapplication, ichiva nechokwadi chisingaenzaniswi nekusimba uye kusimba.

Yakagadzirwa zvine hungwaru nehunyanzvi husingaenzaniswi, yedu Tungsten Carbide Molds inoratidza kuomarara kusinganzwisisike uye kuramba kupfeka, ichivaita sarudzo yekupedzisira yekuumba mabasa mumaindasitiri akaita semotokari, zvemagetsi, nezvimwe.Vimba nemhando idzi kuti dziunze mhedzisiro isina mhosva uye yakawedzera hupenyu, uchishandura maitiro ako ekuumba.

Kupfuura kuomarara kwavo kunoshamisa, yedu Tungsten Carbide Molds inoratidza kunoshamisa kusamira kwekushisa, ichivimbisa kuita kusingachinjiki kunyangwe pasi pemamiriro ekunze anodiwa zvakanyanya.Sangana nekugona kwavo kuchengetedza chaiwo maumbirwo uye kuvimbika, zvichikupa simba rekuwedzera chigadzirwa uye kuderedza mutengo wekugadzira.

PaJINTAI, isu tinodada zvakanyanya mukuendesa zvigadzirwa zvinodarika emhando yepamusoro zviyero.Imwe neimwe Tungsten Carbide Mold inoedzwa kwakasimba, kuve nechokwadi chekufanana uye kugona, zvichiita kuti iwe uwane mibairo isina kunaka mumapurojekiti ako ekuumba.

Gamuchira kunyatsoita uye mutengo-unoshanda neyedu yekutanga Tungsten Carbide Molds, uye uwane mukwikwidzi muindasitiri yako.Batana nesu nhasi kuti unzwe kuita kusingaenzaniswi nema mold aya anounza kumabasa ako ekuumba.

Sarudza JINTAI yekuvimbika, yepamusoro-inoita Tungsten Carbide Molds, uye pupurira kugona kwavo kwechokwadi mukusimudza bhizinesi rako kune hurefu hutsva.Isa odha yako izvozvi uye shandisa simba repamusoro-tier molding mhinduro.

Grade List

| Giredhi | ISO Code | Zvenyama Mechanical Properties (≥) | Application | ||

| Density g/cm3 | Kuoma (HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Inokodzera kunyatso kugadzirwa kwesimbi yakakandwa uye isina-ferrous simbi. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Inokodzera kunyatso gadzira uye semi-kupedzisa kwesimbi yakakandwa uye isina-ferrous simbi, pamwe nekugadzirisa manganese simbi nesimbi yakadzima. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Inokodzera semi-yekupedzisira uye yakakasharara machining eakakanda simbi uye akareruka alloys, uye anogona zvakare kushandiswa rough machining esimbi yakakandwa uye yakaderera alloy simbi. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Inokodzera inlaying rotary impact kucheresa dombo uye rotary impact yekuchera matombo. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Inokodzera kupinza chisel-shaped kana conical mazino mabhiti eanorema-basa kudhirowa dombo michina kubata yakaoma dombo maumbirwo. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Inokodzera kuyedzwa kwekumanikidza kwesimbi simbi uye pombi dzesimbi pasi pepamusoro compression ratios. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Inokodzera kugadzira stamping inofa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Inokodzera kugadzira kutonhora kutsika uye kutonhora kudzvanya kunofira maindasitiri akadai seakajairwa zvikamu, mabhengi, maturusi, nezvimwe. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Inokodzera kurongeka machining uye semi-kupedzisa kwesimbi isina tsvina uye general alloy simbi. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Inokodzera semi-kupedzisa kwesimbi isina tsvina uye yakaderera alloy simbi. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Inokodzera kunyatso kugadzirwa kwesimbi-based, nickel-based high-temperature alloys, uye yakakwirira-simba simbi. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Inokodzera kurema-basa rekucheka kwesimbi uye simbi yakakandwa. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Inokodzera kurongeka machining uye semi-kupedzisa kwesimbi uye simbi yakakandwa. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Inokodzera kunyatso gadzira uye semi-kupedzisa kwesimbi uye simbi yakakandwa, ine mwero wekudyisa mwero.YS25 yakanyatsogadzirirwa kugaya mashandiro pasimbi uye simbi yakakandwa. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Inokodzera zvinorema-basa rekucheka maturusi, zvichipa zvakanakisa mhedzisiro mukuchinjika kwakakasharara kwekukanda uye akasiyana simbi forgings. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Inokodzera inlaying rotary impact yekuchera matombo uye kuchera mune yakaoma uye yakaoma dombo maumbirwo. |

Order Process

Production Process

Packaging