Tsanangudzo

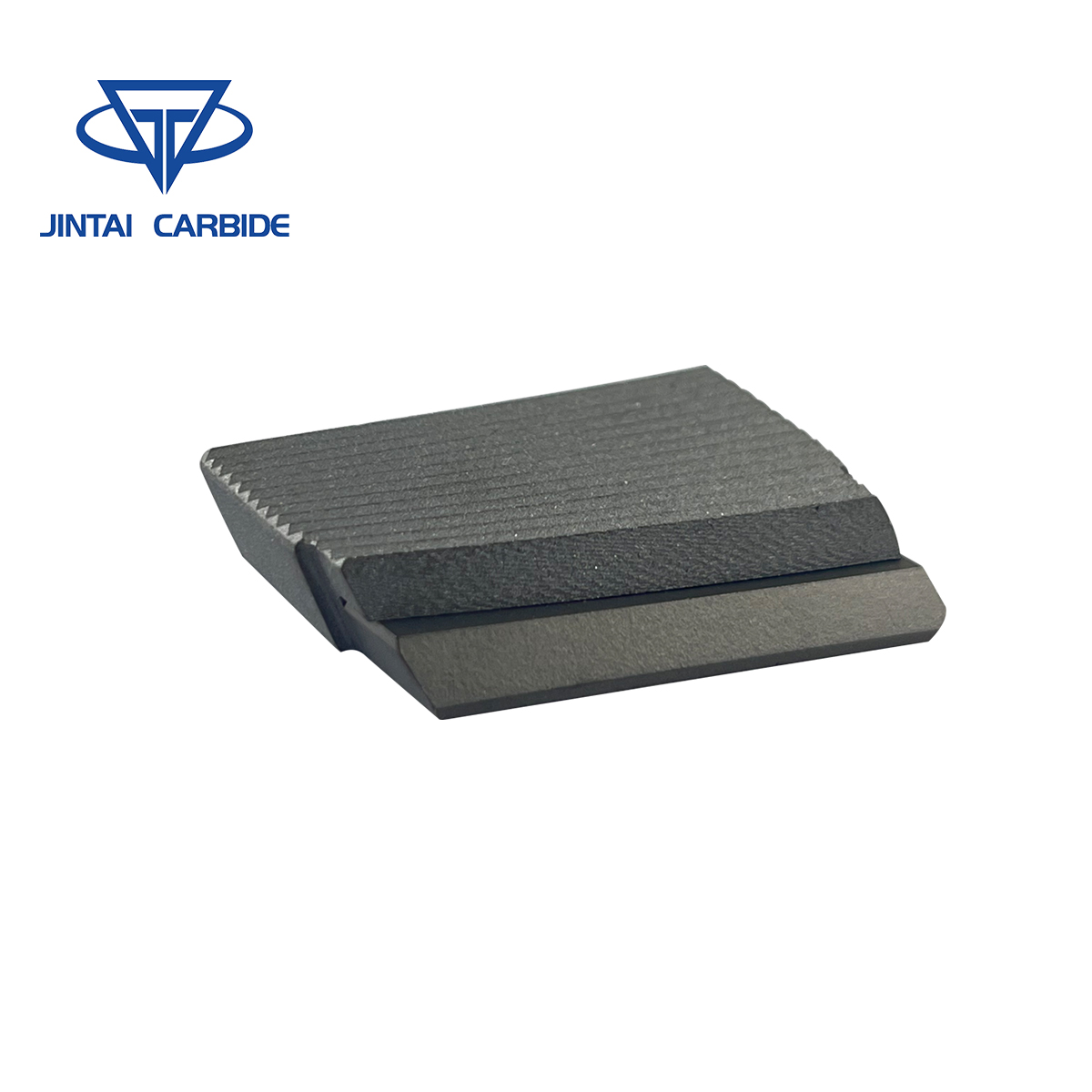

Universal yeHot Fusion / Cold Connection.Inoenderana ne98% yekucheka maturusi emhando pamusika (Fujikura CT-06 CT-08 CT-30 CT-50, Sumitomo FC-6S FC-8R, Furukawa S-326, Inno V7, Jilong KL-21L, nezvimwewo) .Kugadzika kuri nyore, kutenderera kwenguva refu, kucheka chaiko nekona<0.5°.Ultra-yakanaka tungsten simbi inova nechokwadi chekucheka, yakanakisa kupfeka kuramba, uye hunyanzvi hwekuita.Inoshanda zvakanyanya kukucheka maturusi eakasiyana fiber optic brand.

Grade List

| Giredhi | ISO Code | Zvenyama Mechanical Properties (≥) | Application | ||

| Density g/cm3 | Kuoma (HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Inokodzera kunyatso kugadzirwa kwesimbi yakakandwa uye isina-ferrous simbi. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Inokodzera kunyatso gadzira uye semi-kupedzisa kwesimbi yakakandwa uye isina-ferrous simbi, pamwe nekugadzirisa manganese simbi nesimbi yakadzima. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Inokodzera semi-yekupedzisira uye yakakasharara machining eakakanda simbi uye akareruka alloys, uye anogona zvakare kushandiswa rough machining esimbi yakakandwa uye yakaderera alloy simbi. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Inokodzera inlaying rotary impact kucheresa dombo uye rotary impact yekuchera matombo. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Inokodzera kupinza chisel-shaped kana conical mazino mabhiti eanorema-basa kudhirowa dombo michina kubata yakaoma dombo maumbirwo. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Inokodzera kuyedzwa kwekumanikidza kwesimbi simbi uye pombi dzesimbi pasi pepamusoro compression ratios. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Inokodzera kugadzira stamping inofa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Inokodzera kugadzira kutonhora kutsika uye kutonhora kudzvanya kunofira maindasitiri akadai seakajairwa zvikamu, mabhengi, maturusi, nezvimwe. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Inokodzera kurongeka machining uye semi-kupedzisa kwesimbi isina tsvina uye general alloy simbi. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Inokodzera semi-kupedzisa kwesimbi isina tsvina uye yakaderera alloy simbi. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Inokodzera kunyatso kugadzirwa kwesimbi-based, nickel-based high-temperature alloys, uye yakakwirira-simba simbi. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Inokodzera kurema-basa rekucheka kwesimbi uye simbi yakakandwa. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Inokodzera kurongeka machining uye semi-kupedzisa kwesimbi uye simbi yakakandwa. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Inokodzera kunyatso gadzira uye semi-kupedzisa kwesimbi uye simbi yakakandwa, ine mwero wekudyisa mwero.YS25 yakanyatsogadzirirwa kugaya mashandiro pasimbi uye simbi yakakandwa. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Inokodzera zvinorema-basa rekucheka maturusi, zvichipa zvakanakisa mhedzisiro mukuchinjika kwakakasharara kwekukanda uye akasiyana simbi forgings. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Inokodzera inlaying rotary impact yekuchera matombo uye kuchera mune yakaoma uye yakaoma dombo maumbirwo. |

Order Process

Production Process

Packaging