Tsanangudzo

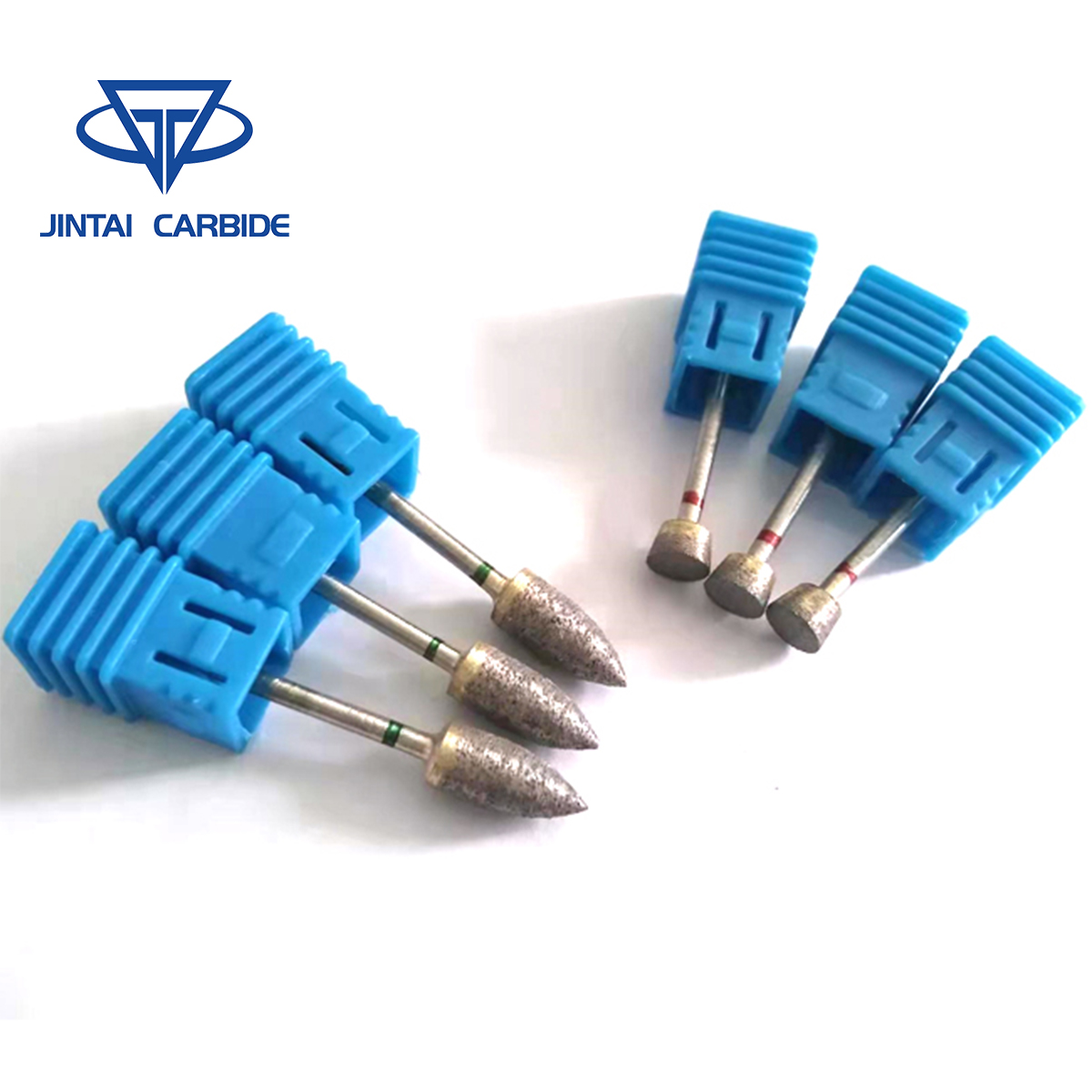

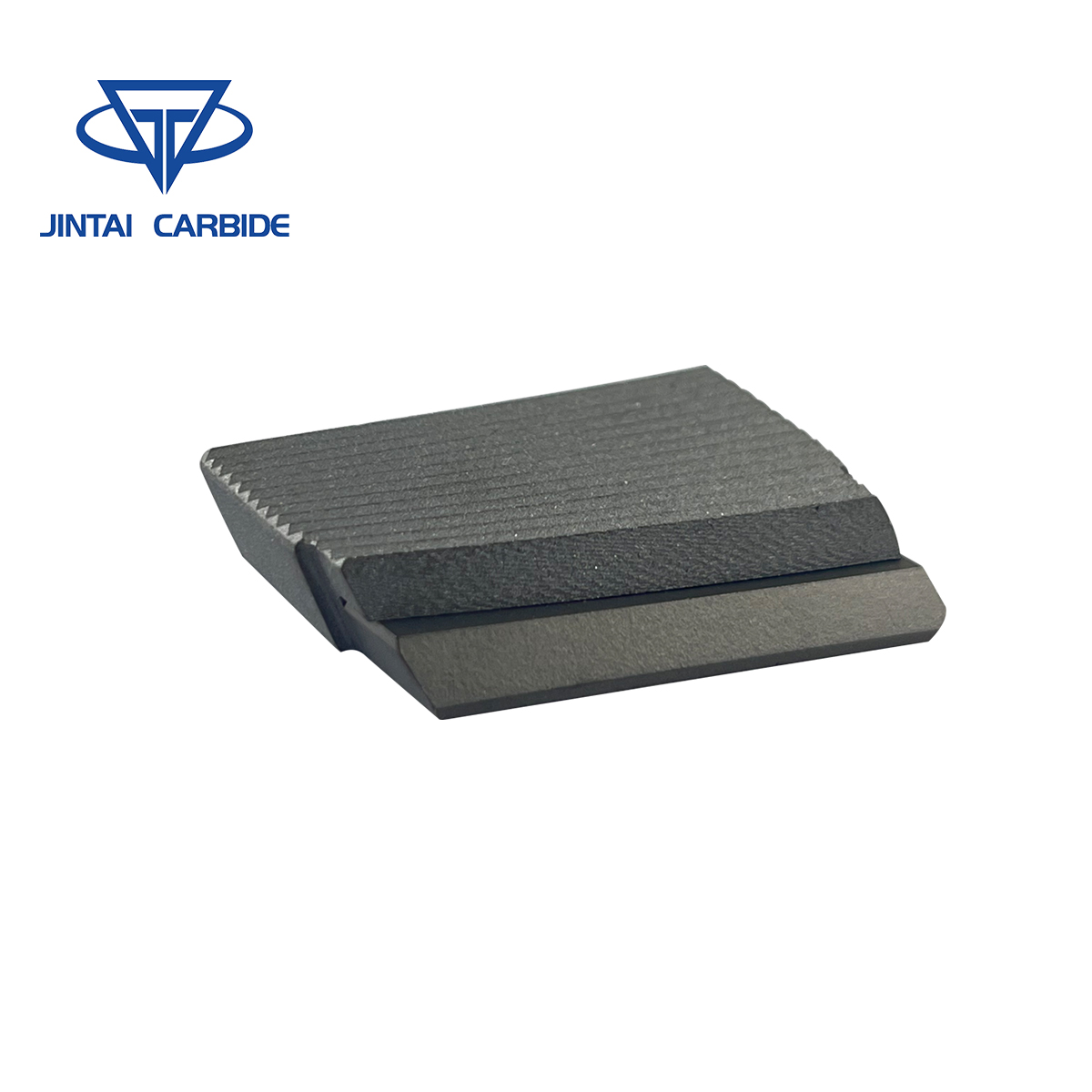

Product Description

Cemented carbide rod ine kutwasuka kwakanaka, kuomarara kwakanyanya, uye kusimba kwakagadzikana.

End mill, reamers uye gravers zvinokurudzirwa.Kuita kwakanakisa kwekucheka kwekukurumidza.Inokodzera kucheka simbi yakaoma, aluminium alloy uye Titanium alloy.Isu tinopa yakasarudzika-yakagadzirwa, padhuze-net-chimiro, premium yekuisa blanks mune simende carbide - inozivikanwawo seTungsten carbide kana yakasimba carbide.

Kuumbwa kwezvinhu:

1.Zvinhu Zvenyama:

A) Kuoma kwakakura kudarika kana kuenzana ne92.8 HRA;

B) Density yakakura kudarika kana yakaenzana ne14.2 g/cm³;

C) TRS yakakura kupfuura kana yakaenzana ne4200 N/mm²;

D) Yemahara yeETA chikamu mamiriro;

E) Hapana kusvibiswa nezvimwe zvinhu;

F) Porosity = A00 / B00 / C00;

G) Saizi yezviyo yakafanana uye inowirirana.Hapana saizi yezviyo inogona kuve yakakura kupfuura yakatsanangurwa.

H) Chromium carbide zviyo kukura inhibitor chete.

2.Zvose zvinogadzirwa, zvipfeko zvinoshandiswa muGermany, Switzerland, michina yekugadzirisa;

3.Iyo inokurudzirwa kucheka isingasviki 60HRC;

Feature

1. 100% mhandara mbishi.

2. Mhando dzakasiyana dzemagiredhi dziri kuwanikwa zvichienderana nekushandiswa kwemutengi.

3. tine nyanzvi yepamusoro yekugadzira mutsara uye inspection equipments kuti tive nechokwadi chemhando yepamusoro yezvigadzirwa.

4. Precision Ground uye high polishing process

5. Kuramba kupfeka kwepamusoro, kuoma kwepamusoro uye kuoma kwemaitiro

6. Advanced tekinoroji , chaiyo kugaya.

Grade List

| Giredhi | ISO Code | Zvenyama Mechanical Properties (≥) | Application | ||

| Density g/cm3 | Kuoma (HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Inokodzera kunyatso kugadzirwa kwesimbi yakakandwa uye isina-ferrous simbi. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Inokodzera kunyatso gadzira uye semi-kupedzisa kwesimbi yakakandwa uye isina-ferrous simbi, pamwe nekugadzirisa manganese simbi nesimbi yakadzima. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Inokodzera semi-yekupedzisira uye yakakasharara machining eakakanda simbi uye akareruka alloys, uye anogona zvakare kushandiswa rough machining esimbi yakakandwa uye yakaderera alloy simbi. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Inokodzera inlaying rotary impact kucheresa dombo uye rotary impact yekuchera matombo. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Inokodzera kupinza chisel-shaped kana conical mazino mabhiti eanorema-basa kudhirowa dombo michina kubata yakaoma dombo maumbirwo. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Inokodzera kuyedzwa kwekumanikidza kwesimbi simbi uye pombi dzesimbi pasi pepamusoro compression ratios. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Inokodzera kugadzira stamping inofa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Inokodzera kugadzira kutonhora kutsika uye kutonhora kudzvanya kunofira maindasitiri akadai seakajairwa zvikamu, mabhengi, maturusi, nezvimwe. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Inokodzera kurongeka machining uye semi-kupedzisa kwesimbi isina tsvina uye general alloy simbi. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Inokodzera semi-kupedzisa kwesimbi isina tsvina uye yakaderera alloy simbi. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Inokodzera kunyatso kugadzirwa kwesimbi-based, nickel-based high-temperature alloys, uye yakakwirira-simba simbi. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Inokodzera kurema-basa rekucheka kwesimbi uye simbi yakakandwa. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Inokodzera kurongeka machining uye semi-kupedzisa kwesimbi uye simbi yakakandwa. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Inokodzera kunyatso gadzira uye semi-kupedzisa kwesimbi uye simbi yakakandwa, ine mwero wekudyisa mwero.YS25 yakanyatsogadzirirwa kugaya mashandiro pasimbi uye simbi yakakandwa. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Inokodzera zvinorema-basa rekucheka maturusi, zvichipa zvakanakisa mhedzisiro mukuchinjika kwakakasharara kwekukanda uye akasiyana simbi forgings. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Inokodzera inlaying rotary impact yekuchera matombo uye kuchera mune yakaoma uye yakaoma dombo maumbirwo. |

Order Process

Production Process

Packaging